What is a HYDRAULIC SNUBBER/SHOCK ABSORBER?

Hydraulic Snubbers are restraining devices used to control the movement of pipe and equipment during abnormal dynamic conditions such as earthquakes, turbine trips, safety/relief valve discharge and rapid valve closure. The design of a snubber allows free thermal movement of a component during normal operation conditions, but restrains the component in abnormal conditions.

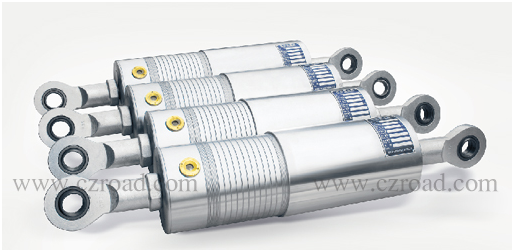

The key part of the hydraulic snubbers/shock absorber

The appearance of hydraulic snubber

How does a HYDRAULIC SNUBBER/SHOCK ABSORBER work?

The basic working principal behind a hydraulic snubber is that under slow (normal) speeds, a piston moves within a hydraulic reservoir pushing hydraulic fluid from the front to the back (or visa versa) of that reservoir. When an impulse load occurs and the piston tries to move at a high speed, a valve will close thereby restricting or blocking the movement of the fluid within the reservoir and subsequently locking the moving piston.

Where is a HYDRAULIC SNUBBER / SHOCK ABSORBER applicable for?

The hydraulic snubber is widely used for resisting vibration of pipeline system and other equipments to nuclear power projects, thermal power projects, wind power project, solar power project, petrochemical projects, steel industry, and etc industries due to its excellent damping performance. And it can effectively protect the pipeline system and equipments from damage of shock load.

The common application situations are as followed:

A, The shock damage which from inside system of pipeline and equipments. / Water Hammer; Steam Hammer; / Steam venting by the safety valve;

The sudden shutdown of the main air valve; / Explosion of the boiler; / Breaking of pipeline / B, The shock damage which from outside system of pipeline and equipments.

Earthquake; / Wind Load; / Accidental Shock from outside

The hydraulic snubber can effectively protect the pipeline system, important pumps, important valves, important pressure vessels, steam turbines, main support beams and so on.