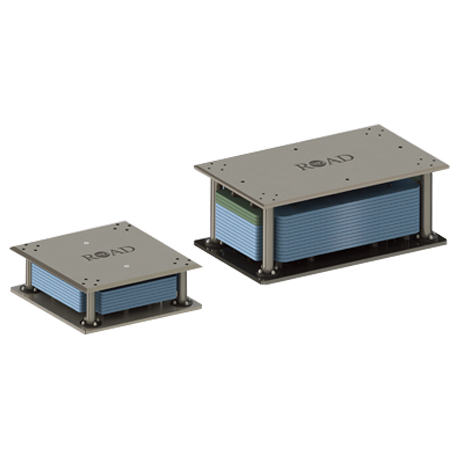

Original Factory Constant Effort Spring Supports - High Quality Buckling Restrained Brace – ROAD Damping Detail:

What is a Buckling Restrained Brace?

The Buckling Restrained Brace(which is short for BRB) is a kind of damping device with high energy dissipation ability. It is a structural brace in a building, designed to allow the building to withstand cyclical lateral loadings, typically earthquake-induced loading. It consists of a slender steel core, a concrete casing designed to continuously support the core and prevent buckling under axial compression, and an interface region that prevents undesired interactions between the two. Braced frames that use BRBs – known as buckling-restrained braced frames, or BRBFs – have significant advantages over typical braced frames.

How does a buckling restrained brace work?

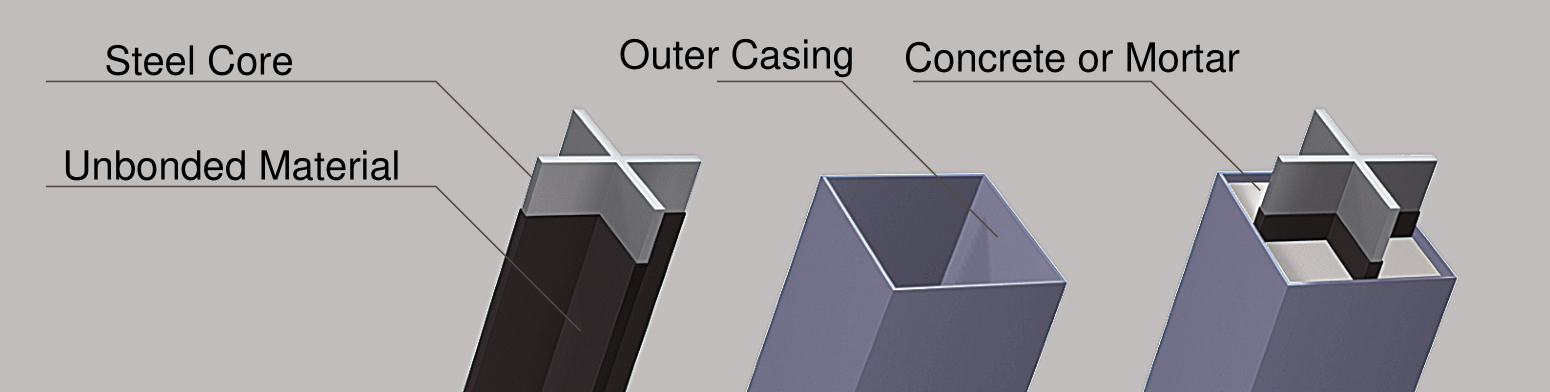

Three major components of a BRB can be distinguished are its steel core, its bond-preventing layer, and its casing.

The steel core is designed to resist the full axial force developed in the bracing. Its cross-sectional area can be significantly lower than that of regular braces, since its performance is not limited by buckling. The core consists of a middle length that is designed to yield inelastically in the event of a design-level earthquake; and rigid, non-yielding lengths on both ends. Increased cross-sectional area of the non-yielding section ensures that it remains elastic, and thus plasticity is concentrated in the middle part of the steel core. Such configuration provides high confidence in prediction of the element behavior and failure.

The bond-preventing layer decouples the casing from the core. This allows the steel core to resist the full axial force developed in the bracing, as designed.

The casing – through its flexural rigidity – provides the lateral support against flexural buckling of the core. It is typically made of concrete-filled steel tubes. The design criterion for the casing is to provide adequate lateral restraint (i.e. rigidity) against the steel core buckling.

What’s the advantage of a buckling restrained brace?

Comparative studies, as well as completed construction projects, confirm the advantages of buckling-restrained braced frame (BRBF) systems. BRBF systems can be superior to other common dissipative structures with global respect to cost efficiency for the following reasons:

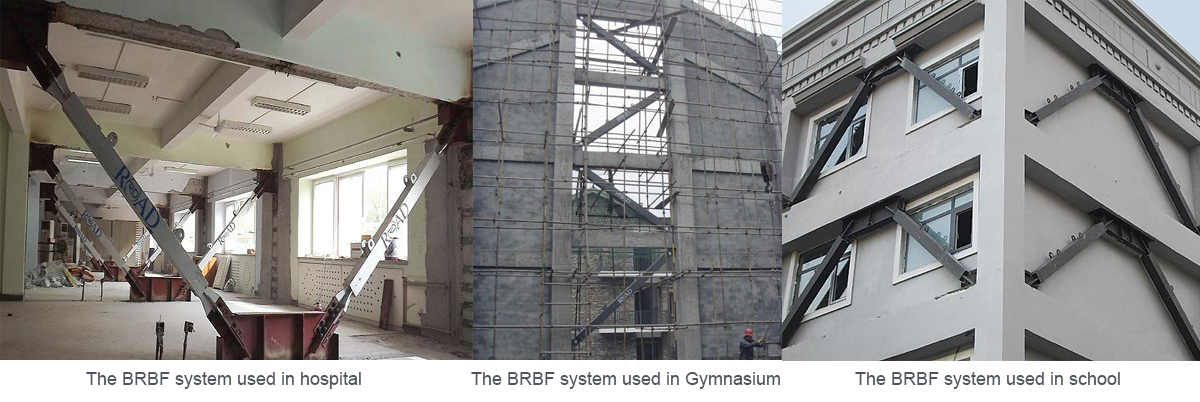

Buckling-restrained braces have energy dissipative behavior that is much improved from that of Special Concentrically Braced Frames (SCBFs). Also, because their behavior factor is higher than that of most other seismic systems (R=8), and the buildings are typically designed with an increased fundamental period, the seismic loads are typically lower. This in turn can lead to a reduction in member (column and beam) sizes, smaller and simpler connections, and smaller foundation demands. Also, BRBs are usually faster to erect than SCBFs, resulting in cost savings to the contractor. Additionally, BRBs can be used in seismic retrofitting. Finally, in the event of an earthquake, since the damage is concentrated over a relatively small area (the brace’s yielding core), post-earthquake investigation and replacement is relatively easy.

An independent study concluded that the use of BRBF systems, in lieu of other earthquake systems, produced a cost per square foot savings of up to $5 per square foot.

What’s the advantage of a buckling restrained brace?

The buckling restrained brace system is not only used in new construction projects, but also the reinforcement and reconstruction projects of the old buildings depends on its excellent performance and low cost. The application fields are as followed.

High-rise buildings / Airports / Schools and hospitals / Conference and exhibition center / Industrial factory building

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for Original Factory Constant Effort Spring Supports - High Quality Buckling Restrained Brace – ROAD Damping, The product will supply to all over the world, such as: Uzbekistan, Wellington, Lithuania, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!