What is a VISCOUS FLUID DAMPER

The viscous fluid dampers are hydraulic devices that dissipate the kinetic energy of seismic events and cushion the impact between structures. They are versatile and can be designed to allow free movement as well as controlled damping of a structure to protect from wind load, thermal motion or seismic events.

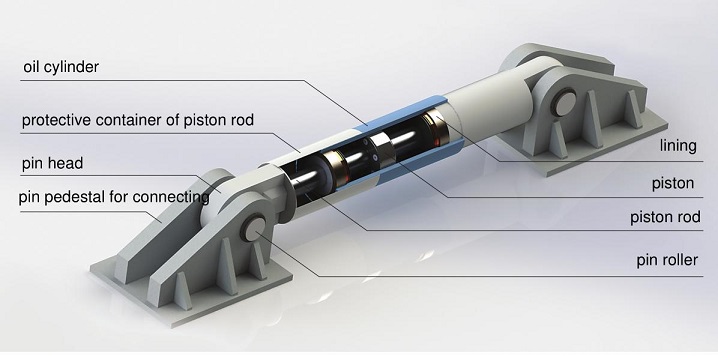

The viscous fluid damper is consist of oil cylinder, piston, piston rod, lining, medium, pin head and other main parts. The piston could make reciprocating motion in the oil cylinder. The piston is equipped with damping structure and the oil cylinder is full of fluid damping medium.

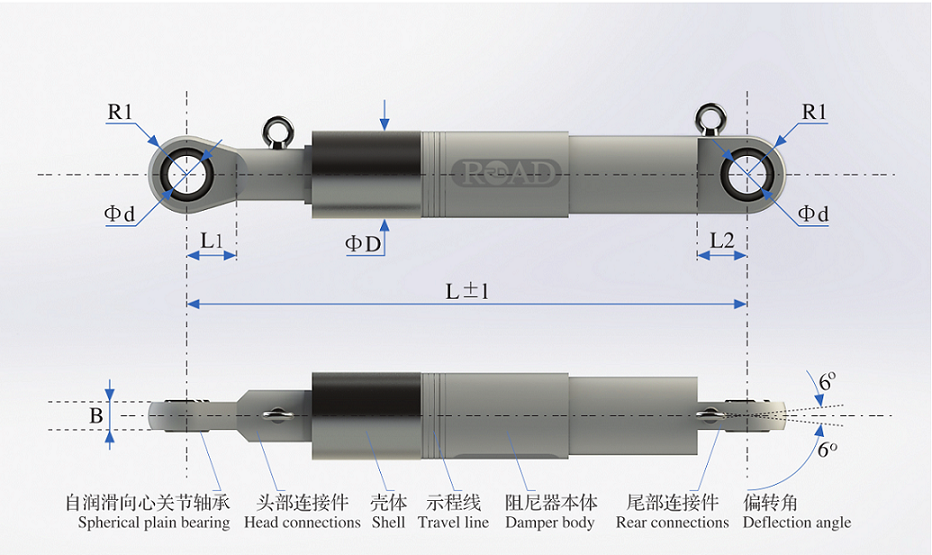

The structure of fluid viscous damper

How does a VISCOUS FLUID DAMPER work?

When the external stimulation(such as earthquake, wind vibration) reaches to the engineering structure, it will be deformed and drive the damper to move, which will occur the pressure difference on the different side of the piston. Then the medium will go through the damping structure and create damping power, which will occur the exchange of power(the mechanical power exchange to heat power). All that will reach the purpose of reducing the engineering structure’s vibration.

Where a VISCOUS FLUID DAMPER applicable for?

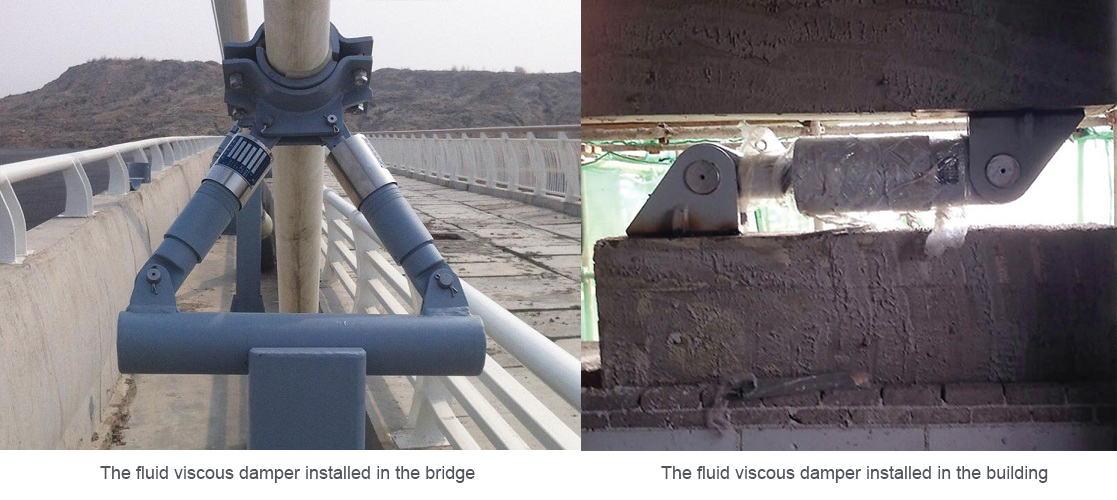

Viscous fluid damper has been widely used in the structure engineering as an high efficiency energy dissipation solution nowadays. The application fields are as followed.

Civil architecture: residence, office building, shopping mall, and other multistoried and longspan buildings.

Lifeline engineering: hospital, school, functional buildings of city and so on.

Industry using: factory building, tower, industry equipment.

Bridges: passenger foot-bridge, viaduct and so on.

Power station, petrochemical, Steel industry.

Why us?

By following the laws and regulation of the industry, our company developed the 3rd generation high-performance viscous fluid damper based on our more than 20 years experience in producing damping products, which is suitable for construction, bridge and other huge engineering projects. And we have totally self-owned intellectual property for the 3rd generation Fluid Viscous Damper.

The 3rd generation VFD adopts the low viscosity silicone oil as the medium to achieve the damping characteristics by the theory of jet flow in the small hole. The 3rd generation VFD’s working theory, the design of damping structure, life and reliability are revolutionary improved than the last generations of products. It represents the highest level of technology among the viscous fluid dampers